C17200 copper cda 172 astm b196 ams 4533 sae j461 rwma class iv c17200 is also known as alloy 25 and is the most commonly utilized beryllium copper alloy and is notable for exhibiting the highest strength and hardness compared to commercial copper alloys.

Beryllium copper c172 sheet.

Also in the fully aged condition the electrical conductivity is a minimum of 22 percent iacs.

To achieve it s high strengths whilst still maintaining acceptable levels of toughness for many industrial applications cda 172 is age hardened.

C17200 also commonly known as alloy 25 is available in round rod bar tube and strip.

It has many excellent properties such as it can attain the hardness as well as the strength of any copper base alloy that is used in commercial purposes.

In its age hardened condition it attains the highest strength and hardness of any commercial copper base alloy.

C172 beryllium copper alloy wire cube2 download pdf.

Its strength and hardness is similar to that of steel.

Beryllium copper c172 is also known as alloy 25 sheet and c17200 sheet.

This alloy also has great galling resisitance.

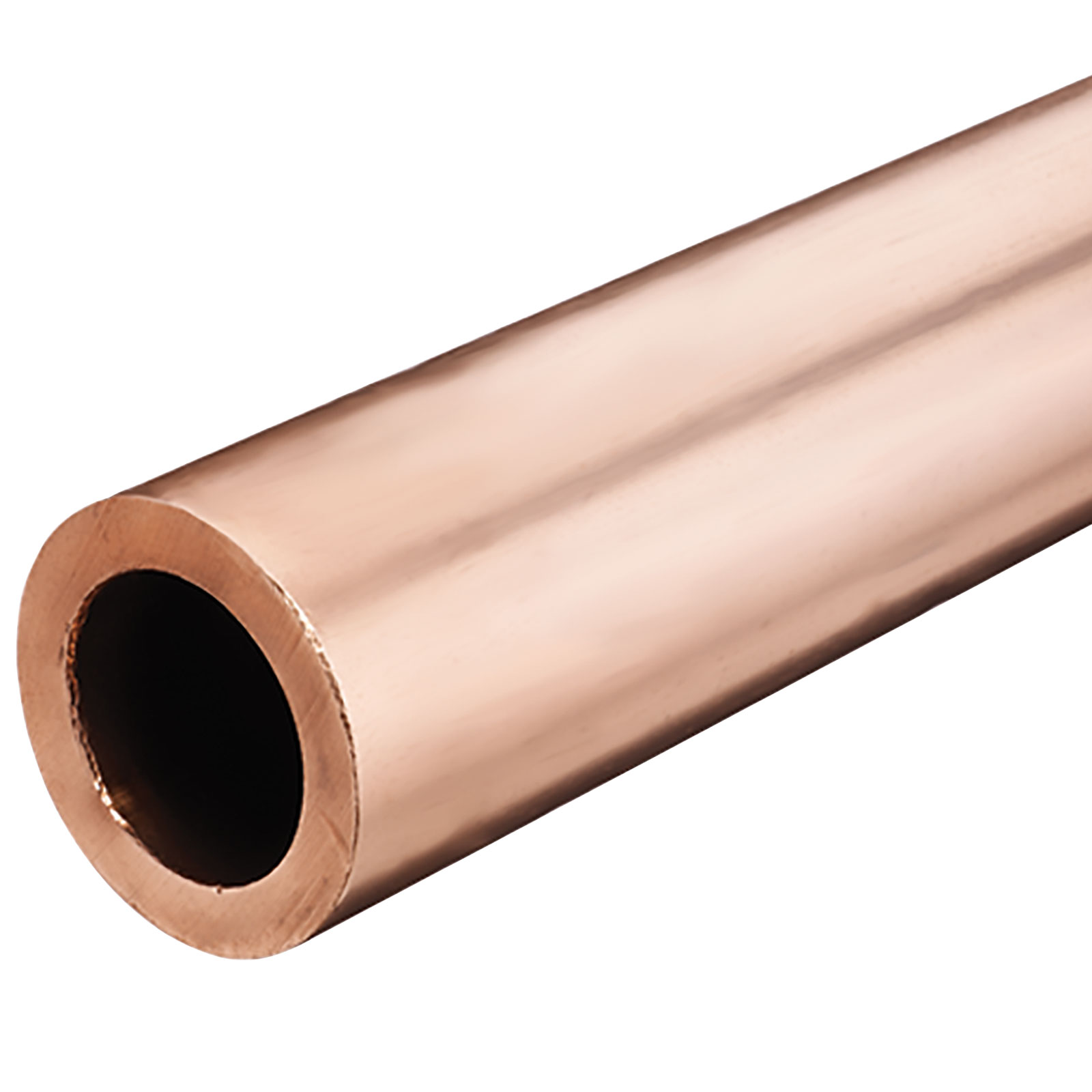

C172 beryllium bronze pipe.

Beryllium copper alloys combine form ability with very high strength properties when aged.

It has excellent metalworking forming and machining qualities.

Beryllium copper combines high strength with non magnetic and non sparking qualities.

Applications are in springs connectors switches and automotive parts.

A low temperature heat treatment 600 degrees for 2 3 hours produces maximum strength and hardness.

C17200 beryllium copper is an excellent material for a number of applications.

Full hard and mill hardened tempers are stocked on a limited basis.

Mead metals carries alloy 172 beryllium copper in annealed quarter hard and half hard tempers from 0 003 to 0 060.

Home c172 beryllium bronze pipe c172 beryllium bronze pipe 3 c172 beryllium bronze pipe 3 beryllium copper.

Copper alloy c17200 is the most commonly specified copper beryllium alloy.

The high strength beryllium coppers c172 can be purchased in the solution annealed or cold worked tempers and can be easily formed or machined.

Add to wishlist added to wishlist removed from wishlist.

Commonly stocked beryllium copper.

C17200 also has siginificant non corrosive properties when exposed to harsh conditions.

17410 17460 and 17510 are also obtainable.

Technical data sheet cda 172 beryllium copper is commonly used due to it s high strength and hardness compared to other commercial copper alloys.

C172 has excellent bearing properties with extremly high compressive strengths.

The ultimate tensile strength can exceed 200 ksi while the hardness approaches rockwell c45.